Effective Dust Control During Wet Season

DUST CONTROL is a year-round challenge for the Mining Industry. It isn’t just a dry-season problem. In fact, managing dust lift-off across the mine site during the wet season, can be the greater challenge of the two.

It’s Important to Know your Chemistry – Rainstorm will teach you.

Successful dust management during wet months requires an understanding of the dust control chemistry used at a particular site. The Pilbara region is known for patchy, localised rain events. These can bring significant falls that will challenge the effectiveness of any dust control chemistry, and just as quickly as they come, they are gone, leaving the site dry again within hours to a day or two.

Often, there will be multiple dry days, even weeks between decent rain events. These are the periods during which it is critical to understand your dust control chemistry and the options available to maximise its effectiveness after a heavy fall.

With an understanding of how the material behaves after a rain event, you can achieve efficient and effective year-round dust suppression. At Rainstorm, we’re all about sharing our knowledge with you and your team so that a heavy downpour doesn’t mean the end of your dust suppression efforts.

Water Alone Just Isn’t Good Enough

The reality is, the old approach to dust control of “throwing water at it” is a thing of the past. Water alone is ineffective, only bringing very short-lived respite from airborne dust. A precious commodity, water is becoming increasingly scarce, and its use is not only becoming increasingly frowned upon but is now formally regulated.

Treated water is a great resource where available, but is costly to purchase. So, whether it’s drawn from natural sources or a treatment plant, the pressure is on to find alternatives to water, minimise what water is necessary and optimise how that water is used.

In fact, so critical is water’s availability and how efficiently it is utilised on site, Lynas managing director, Amanda Lacaze, highlights that the availability of grey water was pivotal to the selection of West Kalgoorlie as the site for the $730 million Lynas refinery.

Lacaze states in an interview with ABC News that “In a country like Australia, where water is at a premium, using grey water is excellent and we re-use it about six times through the process before it ends up in one of our tailings facilities.”

Understanding how Chemical Dust Control Works

When it comes to dust control, chemical methods present a way to reduce water usage (which isn’t effective alone anyway). Understanding how your chosen chemistry works and then effectively handling the impact of a rain event, ensures treated roads retain their integrity and remain dust-suppressed for longer.

Water on Dust Control is Water Lost

A typical scenario on site, just using water for dust control, looks like this: A watercart is filled with up to 120,000 litres of water and run out to wet down a road. Some areas don’t get wet on a first run and those areas are unlikely to be specifically targeted on the next run either.

A watercart heads out repeatedly over the day and it’s usually the case that it’s all too wet for ten minutes, just right for twenty minutes and back to being too dry after that. It will be hours before the watercart gets back for another run and with traffic continuing to use the road, you inevitably see break-up of the surface and generation of dust, which is in fact, your road blowing away.

Despite all those 120,000 litres of water that have been used…

Durable Chemical Dust Control Solutions

By comparison, a DustMagTM treated road during the dry season is rarely watered and even less often graded. With light rain, the surface still doesn’t require any regular special attention.

Following a heavy rain event, you are potentially required to grade a track through the then muddy road surface to allow uninterrupted access for buses, trucks and light vehicles.

Graded in the usual way – outward to the road’s edges – you will end up with all the product pushed into the windrow and forgotten. That’s what you’d do with an untreated road. But on a road treated with chemical dust suppressant, you want to preserve the treated material and effectively re-use it after everything has dried sufficiently to do so.

This is where Rainstorm’s decades of on-site experience and extensive know-how become so invaluable.

Instead of pushing the treated product off the road, we recommend you cut to the centre, forming a clean path on both sides and retention of the treated material down the middle where it can’t be forgotten.

The treated material can (must) then be spread back across the road, ultimately returning the product to where it belongs. Still effective and back to suppressing dust!

When it’s time to push the product back over the road, a light watering to soften the graded material is all that’s required to make it easily spreadable. Gold standard would see a dilute mix of the relevant chemistry applied to topcoat and recharge the running course. If you are dealing with a road that has already been treated multiple times, the topcoat might only be required every second or third rain event.

Emulsions are slightly different, though they also benefit from some remedial attention post rain events.

With experience, this is a simple process, and the Rainstorm will coach and/or supervise this process as needed.

Stay Prepared and it’s not that Complicated

With all chemistries, having some product onsite to patch and repair issues before they completely unravel, is always cheaper than waiting and re-treating a site from scratch.

Water is becoming more and more scarce in the Pilbara and efficient use of your dust control chemistries to fully maximise their effectiveness, along with the support of the Rainstorm team, will allow for cost effective and timely dust control year-round.

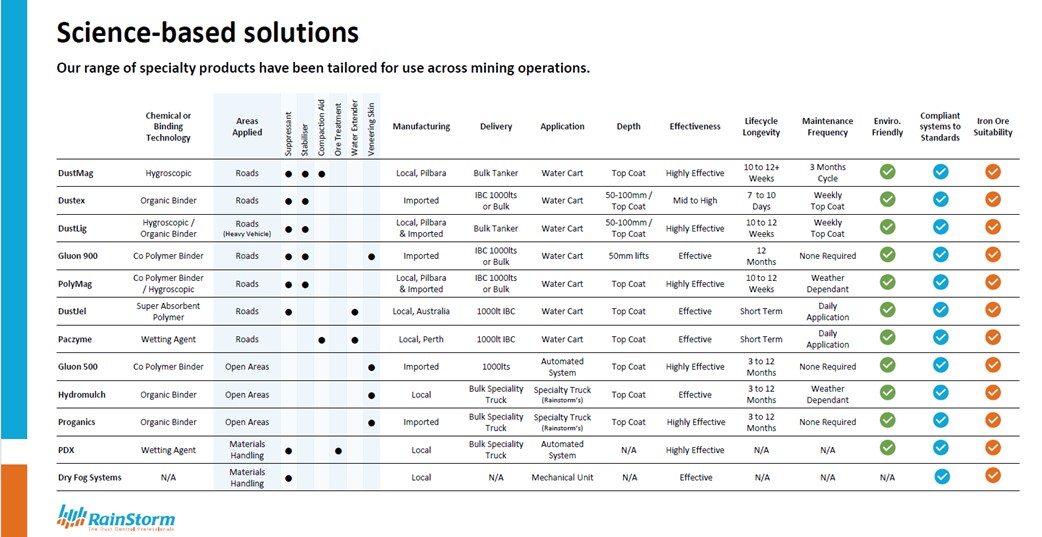

Understanding the basic chemistries allows you to build a science-based dust control method utilising a selection of products that are best suited to your operational requirements, procedures and specific site conditions.

Dust Suppression Results and Client Education are our Top Priority

It is wise to build a relationship with an industry expert like Rainstorm, where we are 100% happy to assist, supervise and share our knowledge so you and your team develop an understanding of available dust suppression options and how to make them work best for you.

At Rainstorm, it’s about results for our clients who we happily support and assist over the entire journey, saving you money and making dust management sustainable for the long term. Reach out to our team today.